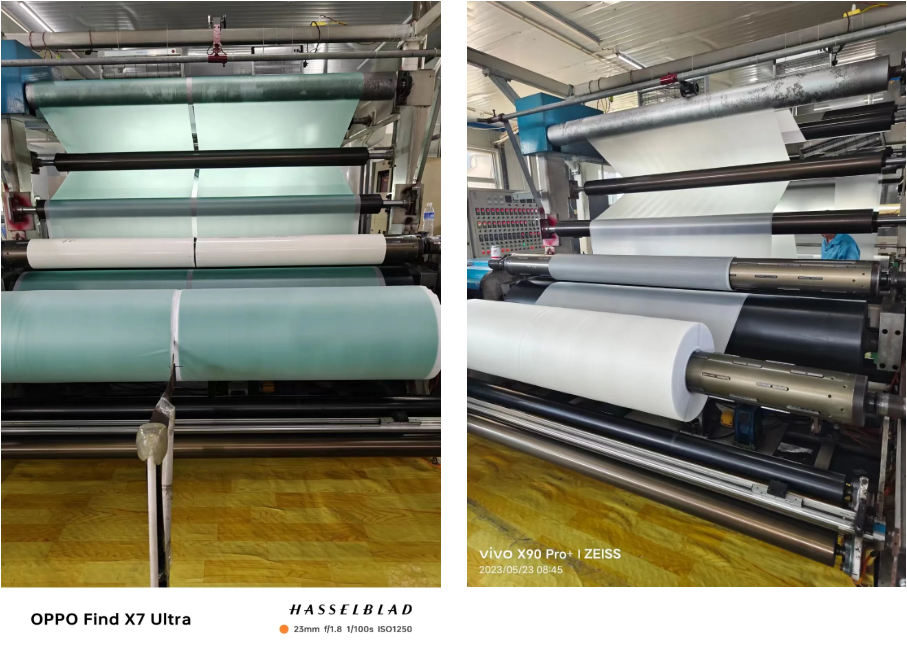

We can be a manufacturer of PVB interlayer

Release time:2024-11-06 12:44:00 click:

PVB interlayer is mainly used for laminated glass, which is a special glass made by sandwiching a layer of PVB film between two pieces of glass and compounding and heating under high pressure. PVB laminated glass is widely used in construction, automobile, photovoltaic and other industries because of its safety, heat preservation, noise control and UV isolation.

Polyvinyl butyral (PVB) is abbreviated as PVB.

It has excellent coating film with high transparency, elasticity, toughness, strong alkali resistance, oil resistance and flexibility, and low temperature impact resistance. Due to its special chemical structure, it has strong bonding with glass, metal, ceramics, plastics, leather and wood.

1) PVB resin

PVB interlayer is mainly made of PVB resin.

PVB resin is non-toxic, odorless, non-corrosive, non-flammable, has good light transmittance, insulation, weather resistance, wear resistance, water resistance, oil resistance, aging resistance, and has special adhesion and light transmittance to inorganic and organic glass. It can be used as an interlayer material for safety glass and can be used as other transparent materials.

2) Plasticizer

Plasticizer 3G8 used in the production of PVB interlayer has good compatibility with PVB resin and has good cold resistance and heat resistance.

3) Additives

In addition to the two main raw materials mentioned above, PVB interlayer also contains additives such as adhesion regulators, antioxidants, and UV absorbers in order to adjust adhesion, improve weather resistance, and isolate UV rays.

As a manufacturer, we have test report certificates and price advantages, and we can also send you samples.

Yihang Marine Service

Tel: +86 335 592 1696

Tel: +86 335 592 1696

+86 137 3033 2982 (Mei)

+86 137 3033 2982 (Mei)